Device connectivity, analytics and monitoring for smart manufacturing.

Real-time Condition Monitoring

Leverage pattern libraries to monitor sensor data to ensure flawless operations.

Automatically detect anomalies and other patterns that signal potential machine failures, other production risks and inefficiencies as early as possible, and get instant notifications to take counter-actions and assure production continuity and optimal performance.

Condition Based Maintenance

Predictive maintenance can transform both your services and your business model.

Old school scheduled maintenance results either in premature maintenance costs or in unavoidable break-down costs as it is not aligned with the maintenance needs of machines operating in different conditions. Granular data analytics helps to deliver maintenance “just-in-time”.

Predictive Quality Analytics

Significantly reduce process-driven losses in quality with granular pattern mining.

It is misleading to measure process and product quality at single control points in the production process. Processes are dynamic and the root causes of quality issues can be revealed only by the underlying patters in continuous time series measurements. Like an ECG reading, the heartbeats of every process are sealed in time series motifs.

Monetization

Turn vast amounts of data in product improvements and new products.

Granular data fuels the digital transformation. Use it to optimize or to monetize. New revenue streams emerge from data-driven insights which R&D and engineering turn into products quickly. Data reduces time to market for new product development or product improvements.

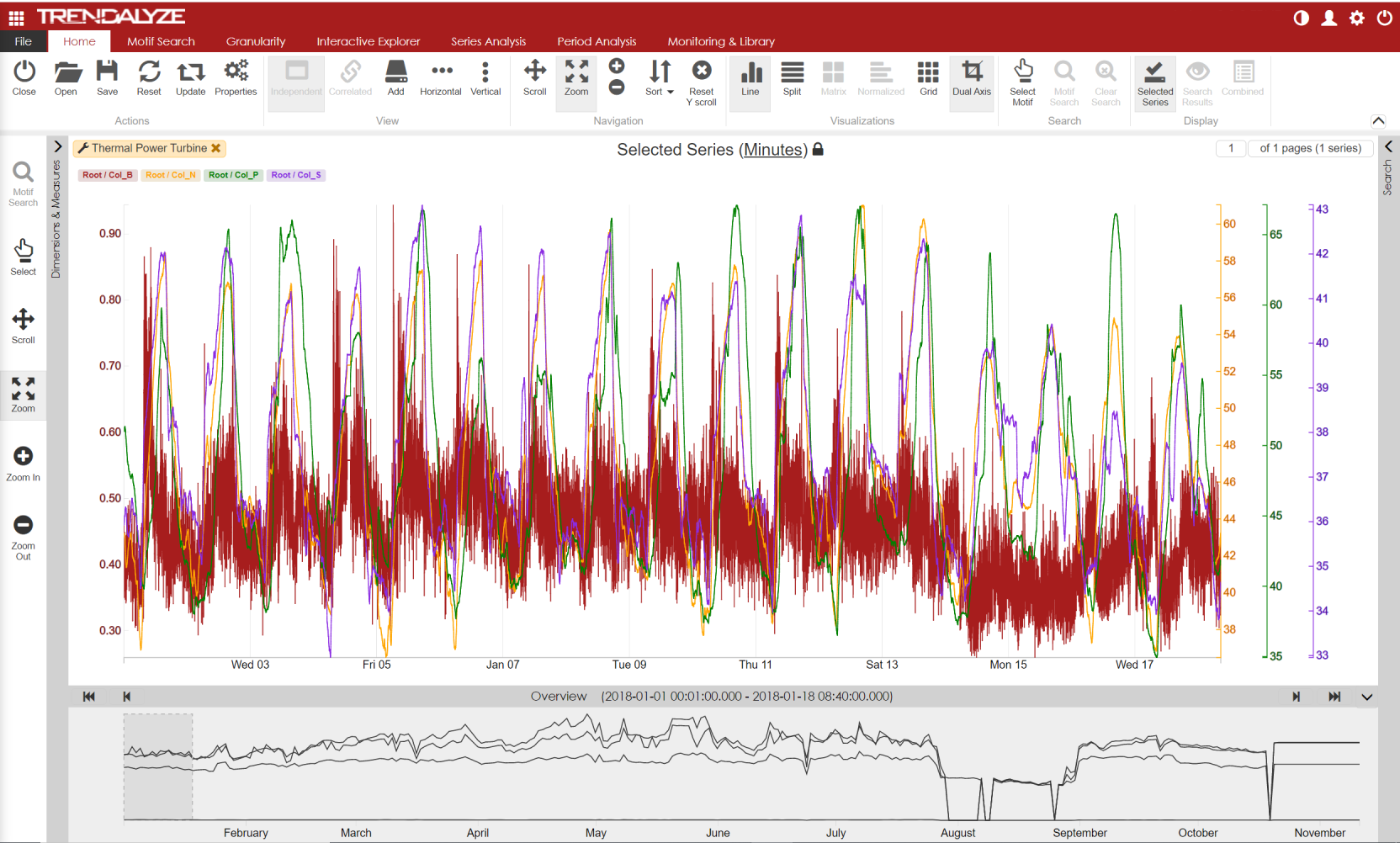

Visualize and Analyze Your Operational DNA

Today manufacturing processes produce a lot of granular data due to rapid cost reductions and improvements in data collection, wireless, and storage technologies. The challenge, however, is that the ability to exploit this data to improve process yields, asset performance optimization, and operational equipment efficiency. The flood of data is making things worse by overwhelming the people tasked with the analysis and the decision making. With Trendalyze manufacturers can deploy operational analytics analytics quickly, with very limited upfront investment and by leveraging the existing business and operational teams to deliver results quickly. Domain experts can easily pull the golden nuggets from the haystack.

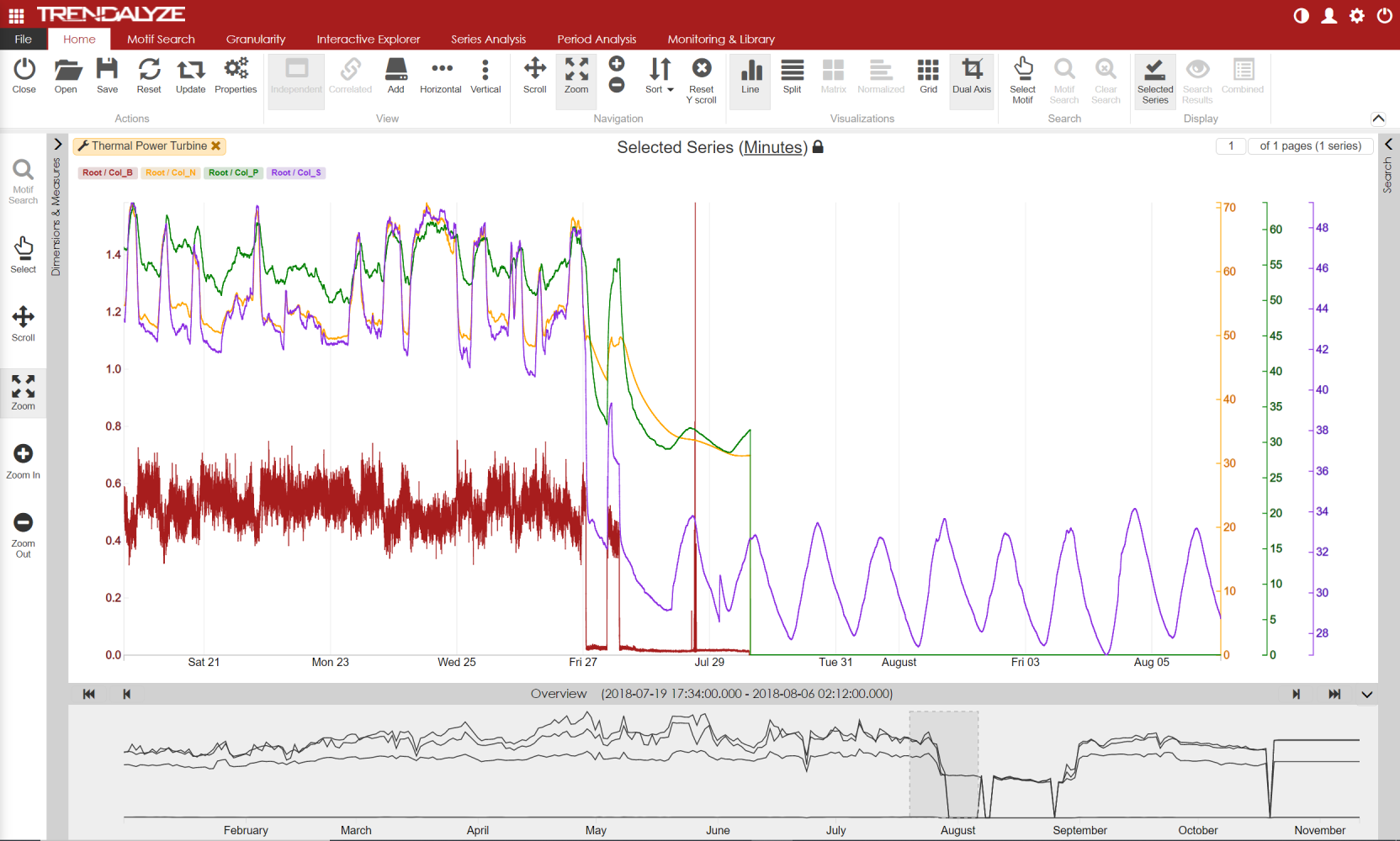

Get Deep Insights About the Meaningful Patterns

Dashboards, rules, thresholds, formulas, and theory-based models do not reveal the full picture nor can scale to the growing volumes of data. Advanced process control approaches like the statistical multivariate models are too process-specific and require long and costly machine learning modeling. Forensic root-cause analysis can take weeks and months to complete and requires writing code for complex queries against time historians. Many operational engineers have told us: “When I see a fault pattern, I want find if and when it has happened before.” Finding similar recurring patterns reveals both the root cause and the solution to many operational problems.

Finding the Golden Nuggets to Improve Operations

A pragmatic approach is need that empowers the professionals who make the decisions to identify with raw materials, process configuration, and machine performances. Engineers need the tools that put under the microscope the operational DNA and help them spot meaningful signals and early warning signs that had plagued operations previously. Threndalyze Motif Intelligence leverages mathematical search algorithms and interactive visualizations to organize the haystacks of data. One can find patterns, search for similar patterns and iteratively pull all relevant patterns to fully understand the operational DNA. The screen shot shows the yellow pattern that brings the other two process (red and green) down.